High Temperature

Film Capacitors

This product family is utilized for drilling and pumping equipment in the oil, gas, and geothermal industries, and also supports specialty aerospace applications and military.

This product family is utilized for drilling and pumping equipment in the oil, gas, and geothermal industries, and also supports specialty aerospace applications and military.

The Advanced Conversion High Temperature Film product line is a result of a partnership

with W. L. Gore & Associates.

Advanced Conversion is the exclusive supplier of this technology featuring GORE® High Temperature Film to the Oil, Gas, and Geothermal Energy Markets. We are only one of two suppliers to all other industry applications.

This patented technology provides a unique combination of self-healing, resistance to extreme vibration and shock, as well as an ability to run reliably for over 1000 hours at 200°C. Gore has specifically qualified our Production Line capability to deliver these parts (Gore Product Integrity sheet).

We currently offer 400V and 600V operating voltage versions with 800 and 1200V versions in development.

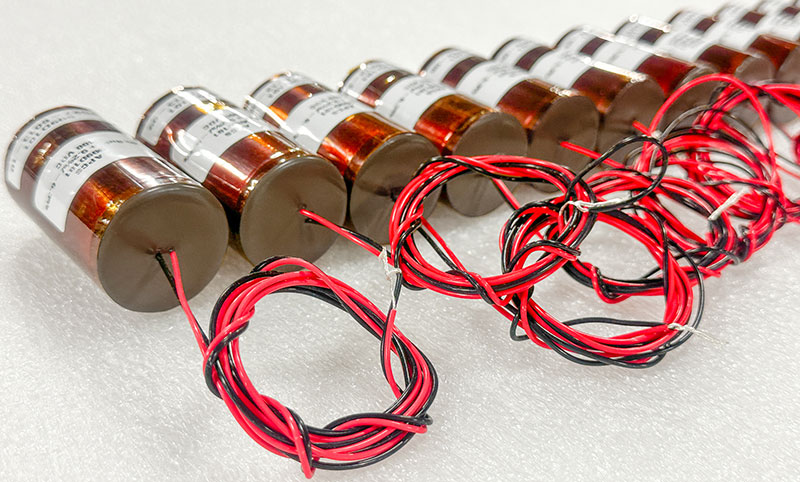

Many “wrap and fill” parts are available now for your high-temperature testing and evaluation. These are typically implemented as banks or arrays to create the desired final capacitance and voltage for the system.

These parts provide a simple way to test the capacitor characteristics and to understand what is ultimately needed for your application, whether it’s a single device or a bank of capacitors. Once you have determined your full system needs, you can order more of these standard parts or our team can design a custom, space-efficient, single-ring solution.

To find out more, visit our High Temp Technology or Oil & Gas Industry pages.

Most products are available in stock either direct from Advanced Conversion or through one of our distributors.

All of the Advanced Conversion winding shapes (Power Rings) and connection systems (integrated capacitor/bus) discussed on the website are also possible.

Do you want to see how your needs can be addressed?

Once you are ready to advance your system ideas and needs to the next generation contact our technical team

or to ask for a quote at [email protected]

Also find below a list of frequently asked questions and answers.

| DC Volt (Vdc) | CAP. (μF) | Standard Part # | Nominal Case Outside Diameter (mm) ± 3.0 mm |

Nominal Overall Height (mm) |

RMS Current at 85°C |

|---|---|---|---|---|---|

| 400 | 25 | 8031G025-XX-X | 26 mm | 62.00 mm | N/A |

| 400 | 30 | 8031G030-XX-X | 29 mm | 62.00 mm | N/A |

| 400 | 40 | 8031G040-XX-X | 34 mm | 62.00 mm | N/A |

| 400 | 50 | 8031G050-XX-X | 39 mm | 62.00 mm | N/A |

| 400 | 60 | 8031G060-XX-X | 44 mm | 62.00 mm | N/A |

| 400 | 70 | 8031G070-XX-X | 47 mm | 62.00 mm | N/A |

| 400 | 80 | 8031G080-XX-X | 50 mm | 62.00 mm | N/A |

| 400 | 90 | 8031G090-XX-X | 52 mm | 62.00 mm | N/A |

| 400 | 100 | 8031G0100-XX-X | 54 mm | 62.00 mm | N/A |

Currently 400 and 600V rated parts are available. 800 and 1200V rated parts are in development.

100μF Wrap and Fill packaged parts and 1000μF Ring parts are available.

Wrap and Fill parts are typically “banked” together by the customer or board mounted. Please contact our applications team for ring shaped suggestions.

If 200°C and the rated voltage are not exceeded, you should expect to see over 1000 hours of reliable service.