Technology overview

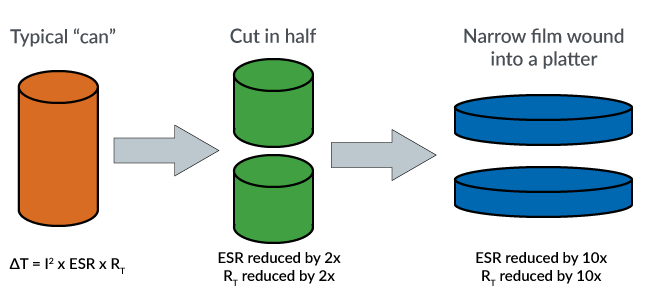

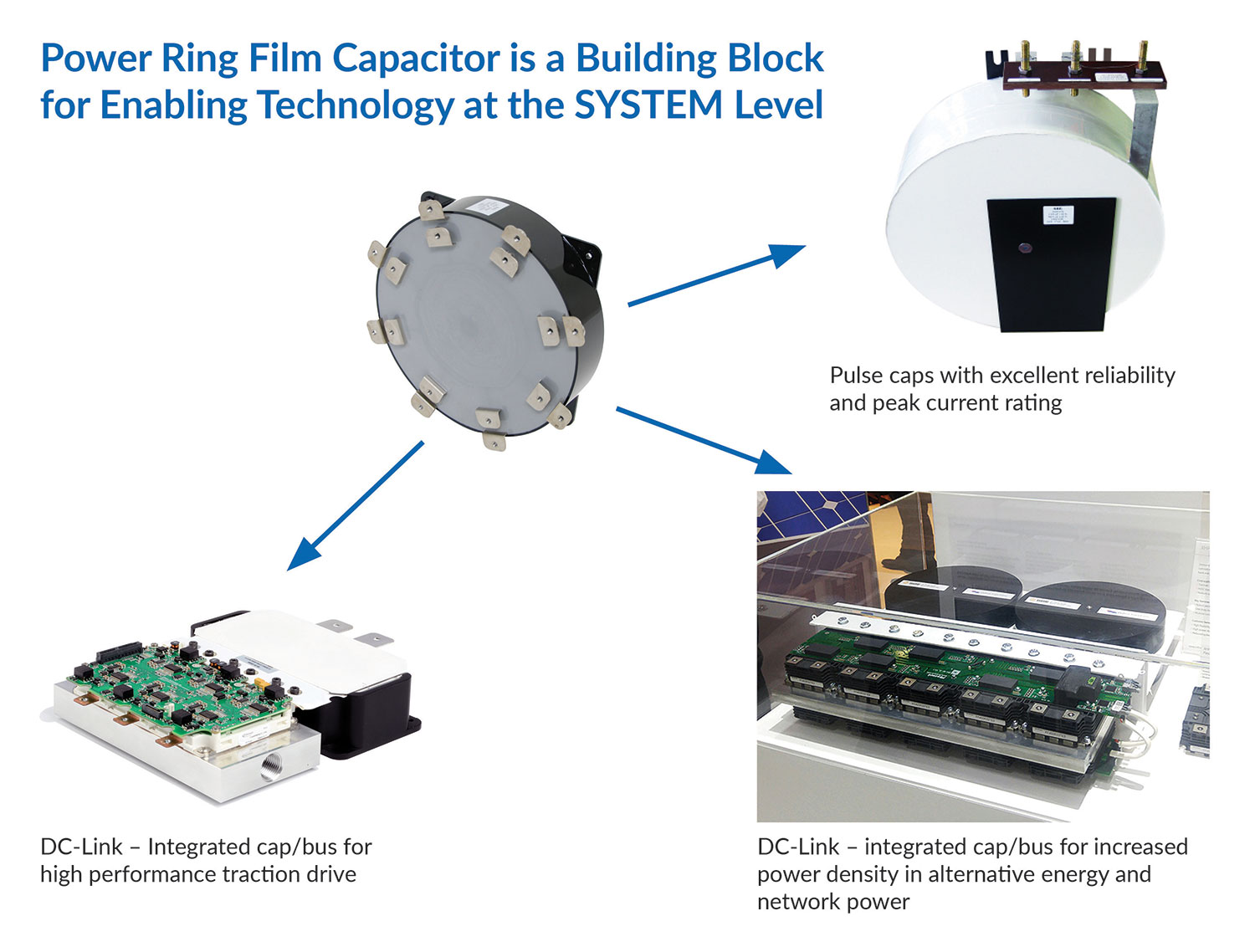

Advanced Conversion provides novel annular form factor film capacitors using a specially developed proprietary winding technology. Our capacitors minimize the ratio of winding height to diameter such that the best possible thermal performance is achieved while maximizing the end connection area. These unique windings are combined with optimized connections, bus structures, and packaging to provide system-level solutions for power converters in electric vehicles, aerospace, grid-tied electric utility, network power, medical, and pulsed power applications. We offer our annular capacitor windings surface mounted on bus structures fabricated in-house to realize state-of-the-art DC-link topologies that enable high-speed switching inverters based on wide bandgap devices.

Advanced Conversion provides novel annular form factor film capacitors using a specially developed proprietary winding technology. Our capacitors minimize the ratio of winding height to diameter such that the best possible thermal performance is achieved while maximizing the end connection area. These unique windings are combined with optimized connections, bus structures, and packaging to provide system-level solutions for power converters in electric vehicles, aerospace, grid-tied electric utility, network power, medical, and pulsed power applications. We offer our annular capacitor windings surface mounted on bus structures fabricated in-house to realize state-of-the-art DC-link topologies that enable high-speed switching inverters based on wide bandgap devices.

The Power Ring Film Capacitor was originally developed under an SBIR grant from the United States Department of Energy and additional investor-matched Recovery Act funding. This work led to multiple patents, manufacturing processes, material data, analysis, testing capabilities, and a production facility capable of producing 100,000 film capacitor assemblies per year. We have since added capacity in at our Colorado and China facilities.

The Power Ring Film Capacitor was originally developed under an SBIR grant from the United States Department of Energy and additional investor-matched Recovery Act funding. This work led to multiple patents, manufacturing processes, material data, analysis, testing capabilities, and a production facility capable of producing 100,000 film capacitor assemblies per year. We have since added capacity in at our Colorado and China facilities.

Today, Advanced Conversion capacitors are featured in an array of specialized fields, showing that our designs can be employed for any challenging use. Our winding technology is industry leading and unique among alternative solutions. Fully automated, the cost to value supplied in your application will meet or exceed your expectations.

Our technology portfolio features a variety of high-performance and high-temperature DC link, pulsed power, and AC filters. To find more information on each, click on the individual links below, or find them on the main navigation bar under the category, Technology.